Control Practices

Training Details

The SSMI® Control Practices Training Program provides students with the prerequisite training needed to develop the knowledge and skills necessary for understanding and applying the essential concepts, tools, procedures, practices needed to use statistical process control (SPC). Upon completion of this training, the participant will be able to implement and sustain several common types of SPC charts for variables and attribute data. Major emphasis is placed on the ways and means for centering a process and reducing its range of operation; thereby, increasing process capability while concurrently reducing the probability of defects. Of course, this leads to the reduction of overall operating costs.

Instruction includes how to plan a control chart study, how to implement successful sampling strategies, how to compute the underpinning statistics, as well as how to uncover nonrandom trends and events commonly associated with underperforming processes. In addition, you will learn many of the “real world” situations in which SPC charts can be effectively employed to enhance control, reduce variation and generate additional value, to the benefit of the customer and provider. Reinforcement of major concepts, techniques, and applications is realized through exercise, scenarios, case studies, and field studies.

The body of knowledge associated with this program of study is organized into three primary segments: Global Concepts, General Practices, and Technical Practices.

Global Concepts

- Training Orientation

- Breakthrough Vision

- Process Management

General Practices

- Quality Tools

- Basic Statistics

- Continuous Capability

- Discrete Capability

Technical Practices

- Hypothesis Testing

- Confidence Intervals

- Control Methods

- Measurement Analysis

To obtain the SSMI® Control Practices Certification, participants are required to complete the following requirement:

Completion of 9 Knowledge Assessments Exams. Each module assessment comprises of 6 to 70 questions which participants need to score more than 70%

The SSMI® Control Practices program has a duration of 60 hours of video lessons.

Our Training Formats

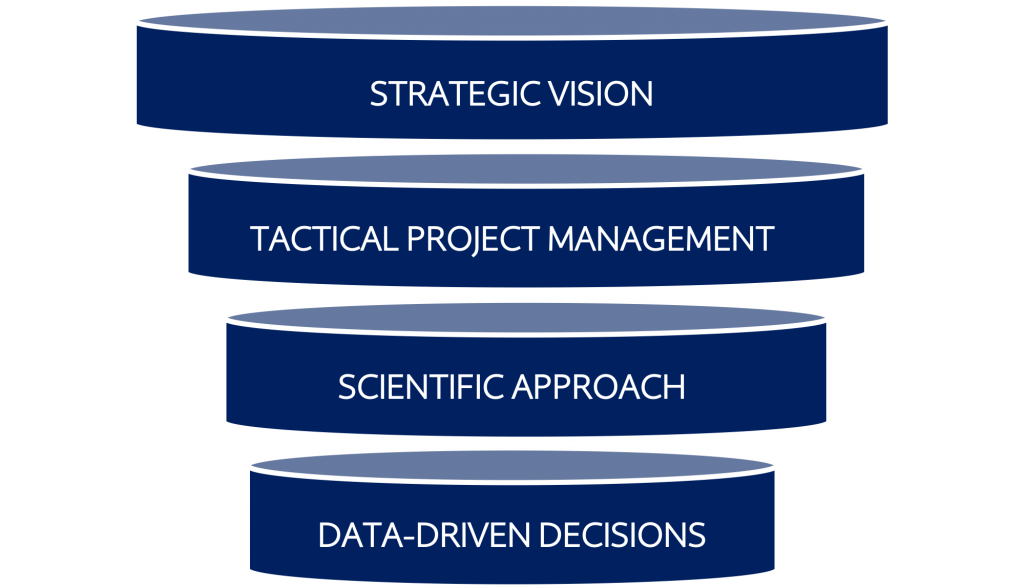

Benefits of a Lean Six Sigma Certification

Improves Execution

Builds customer loyalty

Generates greater returns

Certifies your talent

Improves work performance

Open new doors

Applies everywhere

Program Architect

Dr. Harry has been widely recognized as the principal architect and pioneer of Six Sigma, developed in Motorola where he was responsible for the research and development of advanced engineering and statistical models. All the training offered by SSMI are the result of 30+ years of application of these models. Even though many companies worldwide now offer Lean and Six Sigma training, SSMI is the only Institute in the world to possess the original body of knowledge and framework which made this methodology one of the most successful and powerful in the world.