Diagnostic Practices

Training Details

The SSMI® Diagnostic Practices Training program will endow the participant with the knowledge and insights necessary to judiciously plan and successfully execute a diagnostic study. Participants will learn how to fully characterize the statistical performance of a process and identify the dominant families of variation.

Students will discover a selected array of powerful analytical and statistical tools that are essential for isolating critical sources of variation related to process centering and spread. Major emphasis is given to the methods and techniques for statistically analyzing, describing, and displaying performance data for virtually all types of products, processes, services and transactions. In particular, the participant will learn how to select the right variables and parameters for inclusion in a factorial experiment. Participants will learn how to establish operating tolerances for almost any type of product, process or service.

Of special interest, the participant will learn the theory and application of common sampling methods as well as how to draw valid conclusions and make statistical inferences from a sampling distribution. In support of this, the participant will also learn how to draw such conclusions with known degrees of statistical risk and confidence.

The knowledge gained from this curriculum is paramount to the effective use of performance metrics and indices of process capability. Reinforcement of the major techniques and applications is realized through exercises, scenarios, and case studies.

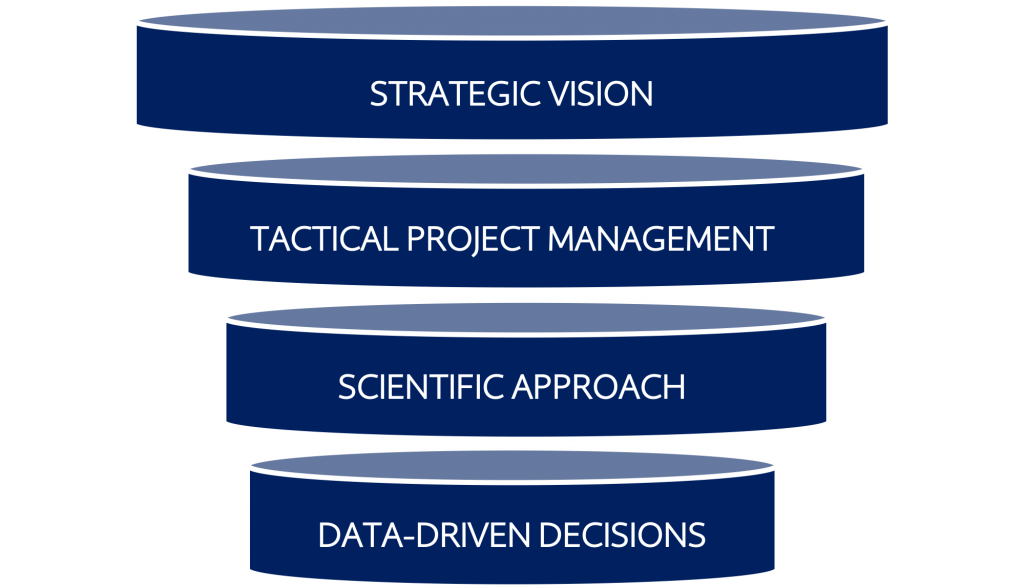

The body of knowledge associated with this program of study is organized into three primary segments: Global Concepts, General Practices and Technical Practices.

Global Concepts

- Training Orientation

- Breakthrough Vision

- Business Principles

- Process Management

General Practices

- Quality Tools

- Basic Statistics

Technical Practices

- Hypothesis Testing

- Confidence Intervals

- Parametric Methods

- Chi-Square Methods

- Survey Methods

- Non-parametric Methods

- Measurement Analysis

To obtain the SSMI® Diagnostic Practices Certification, participants are required to complete the following requirement:

Completion of 11 Knowledge Assessments Exams. Each module assessment comprises of 6 to 102 questions which participants need to score more than 70%

The SSMI® Diagnostic Practice Training has a duration of 60 hours of video lessons.

Our Training Formats

Benefits of a Lean Six Sigma Certification

Improves Execution

Builds customer loyalty

Generates greater returns

Certifies your talent

Improves work performance

Open new doors

Applies everywhere

Program Architect

Dr. Harry has been widely recognized as the principal architect and pioneer of Six Sigma, developed in Motorola where he was responsible for the research and development of advanced engineering and statistical models. All the training offered by SSMI are the result of 30+ years of application of these models. Even though many companies worldwide now offer Lean and Six Sigma training, SSMI is the only Institute in the world to possess the original body of knowledge and framework which made this methodology one of the most successful and powerful in the world.